While you may have heard about 3D printing, you may not be aware of how the process works, or that people are using the 3D printer for incredible projects like office buildings in India or to replace the tent cities in places like El Salvador. We’re going to explore the world of 3D printing in this article, specifically as it relates to architecture and how it is done around the world. It doesn’t just require a 3D printer, nor can a 3D printer put an entire building together, complete with windows, wiring, and etc. It is, however, possible to lower the cost of a building dramatically by using a 3D printer, and it can be done in less than 24 hours.

Projects have been done all over the world, with various equipment, and to varied results. The best news is that affordable, safe housing can be created for under $4,000 apiece in third world countries. The drawback is that there might not be enough room for them all, so until the 3D printer can be made to accommodate a more vertical build, the experiment continues. India has used a 3D printer to begin building offices, but again, there isn’t much room to spread out.

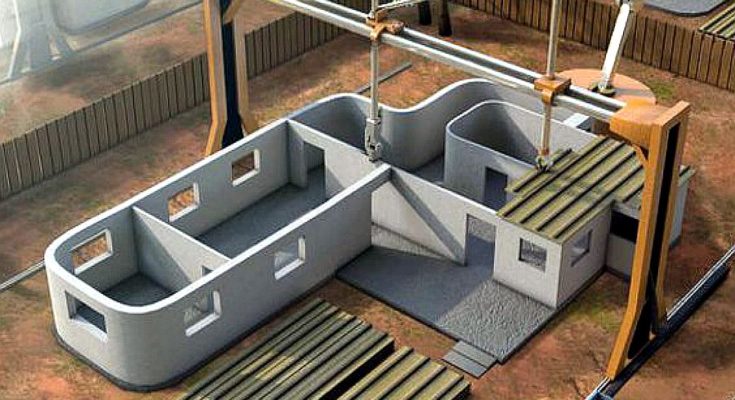

Another bonus to using a 3D printer is that the houses will still need local crews (thereby providing jobs to the nearby population) to complete them. The 3D printer can be used for all the heavy duty work and then crews can come in and tidy up and make what adjustments are necessary before the move in date. The 3D printer begins by using the blueprints and a crane type machine to ‘print’ out the walls in concrete (or whatever other building material is chosen, though concrete is a solid option most often used).

These structures are tough, durable, and are expected to last as long or longer than buildings formed in the regular way.

With 3D printers cutting the time of construction to 24 hours, and slashing prices so dramatically, it might not be long before we see 3D printed houses in our own neighborhoods and towns. Are you ready?